To be closer to customer, Borske make use of the latest IT developments for WEB connection to further improve the efficiency of the service.

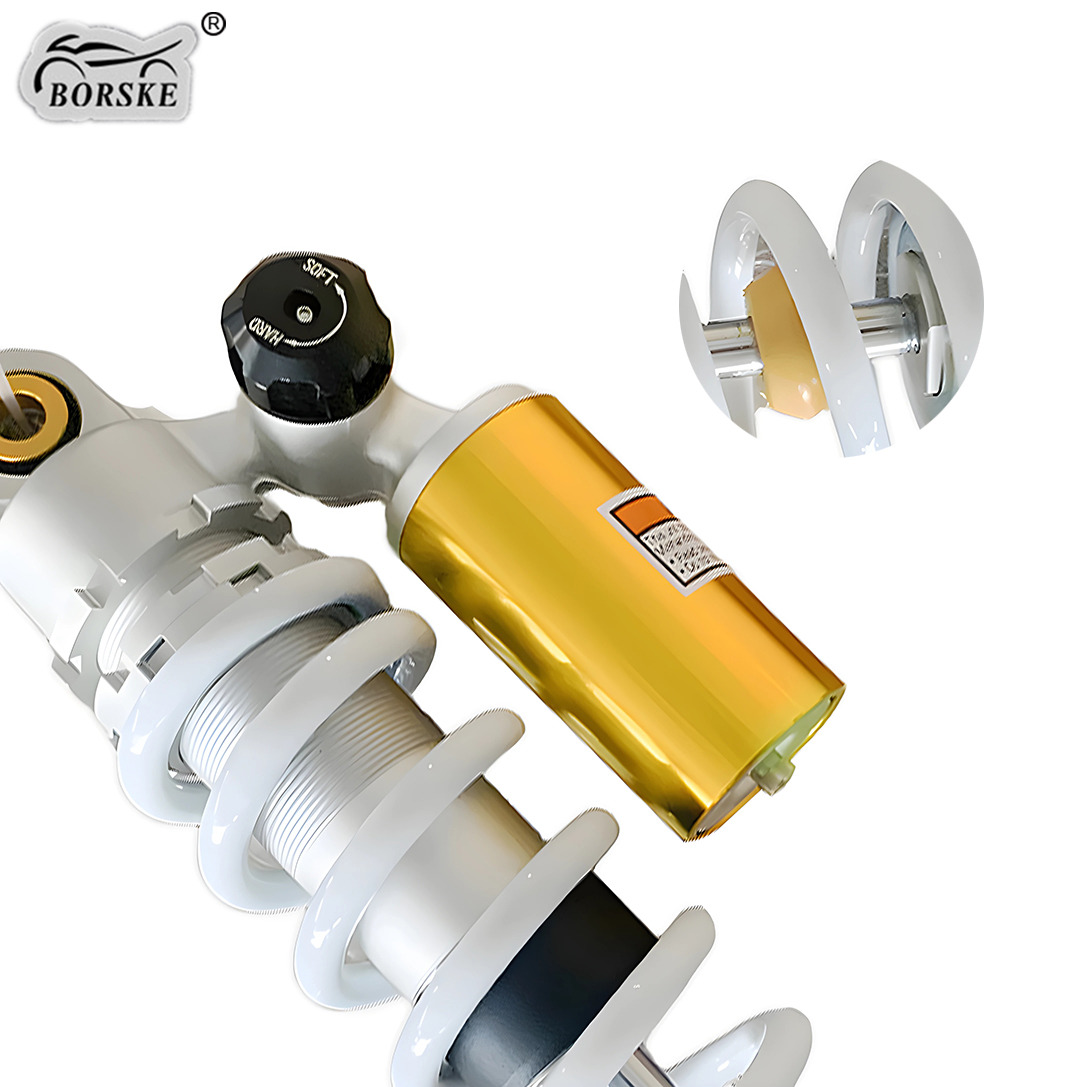

Aluminum alloy ATV Shock Absorber

Aluminum alloy ATV Shock Absorber

Borske motorcycle Parts Company Aluminum alloy ATV Shock Absorber

ATV Shock Absorber

Smooth Riding & Strong Control

–The BSK-ATV0171 atv shock absorber is designed to improve riding comfort and vehicle control on rough terrain. It is suitable for ATVs used on dirt roads, snow, gravel, and light off-road conditions.

Durable Aluminum Alloy Construction

–This shock absorber for ATV is made from high-quality aluminum alloy, offering strong performance with reduced weight. It helps absorb vibration, reduce impact, and improve overall stability during riding.

Adjustable & Practical Design

–The shock absorber ATV comes complete with key components, including a spring and nitrogen system. Riders can adjust the hardness or softness based on real riding conditions, making it suitable for different loads and terrains. The adjustable design helps improve comfort and handling.

Multiple Models & Custom Options

–As one of the professional ATV shock absorber manufacturers, Ningbo Borske Vehicle Parts Co., Ltd. offers multiple shock absorber models for different ATV applications. We also support customization, including mounting hole size, overall length, and other technical parameters, to meet specific customer needs.

Product Highlights

–Aluminum alloy atv shock absorber

–Adjustable spring and damping

–Complete structure with nitrogen system

–OEM & custom solutions available

Get in Touch

7X24 hours hotline, with a complete set of customer management system.

We have a professional R&D team, can be customized according to customer demand for special equipment.

Factory ISO 9001, CE Certificate, QC team for quality controlled by heart. Free spare parts and 1 year’ s warranty.

LOOKING FOR

MOTORCYCLE PARTS & ACCESSORIES?

Ningbo Borske Vehicle Parts Co.,Ltd. is a modern company specialized in motorcycle parts & accessories sold in the foreign market and integrated with R&D and Manufacture.

Reviews

FAQ

A: We offer flexible MOQs to accommodate both startups and large businesses. For standard custom printed cups, our MOQ starts from 50,000 pieces. For simpler designs or stock items, we may offer lower quantities. Contact us to discuss your specific needs.

A: Our standard production lead time is 15-20 days after all details (artwork, specs) are confirmed. Shipping time depends on the destination port and method. Our proximity to major ports like Shanghai and Ningbo ensures fast and efficient logistics. A detailed schedule will be provided with your quote.

A: Absolutely. Our professional design team can provide free basic layout assistance to ensure your artwork is print-ready. We will also perform a pre-press proofing to guarantee the final print quality meets your expectations.

A: Our Class 100K+ clean room, upgraded in 2024, significantly reduces dust and microbial contamination during manufacturing. This ensures superior product hygiene and safety, which is critical for food packaging and required by many international brands and certifications (like BRC).

A: We support secure payment methods including T/T (Bank Transfer) and L/C (Letter of Credit). For new customers, we typically require a 30% deposit with the balance paid before shipment. Terms can be discussed for established partners.

A: Yes, we provide free sample cups for evaluation. Customers only need to pay the courier cost (DHL, FedEx, etc.). This allows you to feel our product quality and print效果 firsthand before placing a large order.

A: Our products and manufacturing process are certified by internationally recognized bodies. Our key certifications include FSC (for sustainable paper sourcing), BRC (for food safety), and BSCI (for social responsibility). These ensure our products meet global market standards.

A: Yes. We offer a range of sustainable options. We use FSC-certified paper from responsibly managed forests. We also offer PLA lining, a bio-based and compostable material, as an alternative to traditional PE plastic lining for certain applications.